Efficiency Motors

including Permanent Magnet Synchronous Motors that ensures

reliable performance even in the most demanding conditions.

Delivering efficiency and innovation to power your business forward.

Motor Type |

Frame |

Power (kW) |

Polarity |

Download |

|---|---|---|---|---|

| Standard Flame Proof Motors | 80 to 315 | 0.37 to 200 | 2, 4, 6, 8 | |

| IE2 Flame Proof Motors | 80 to 315 | 0.37 to 200 | 2, 4, 6 | |

| IE3 Flame Proof Motors | 80 to 315 | 0.75 to 180 | 2, 4, 6 | — |

| Non – Sparking Motors | 63 to 400 | 0.12 to 560 | 2, 4, 6, 8 | |

| Increased Safety Motors | 63 to 355 | 0.12 to 400 | 2, 4, 6, 8 | — |

Motor Type |

Frame |

Power (kW) |

Polarity |

Download |

|---|---|---|---|---|

| Cane Unloader Motors | 160 to 225 | 11 to 30 | 6 | |

| Marine Duty Motors | 63 to 450 | — | — | — |

| Roller Table Motors | As per requirement | — | — | — |

| Railway Auxilliary Motors | As per requirement | — | — | — |

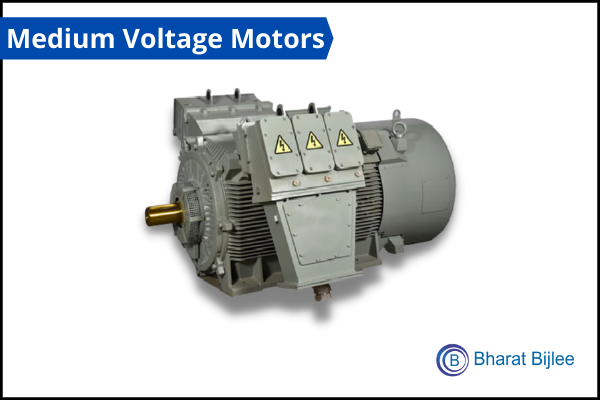

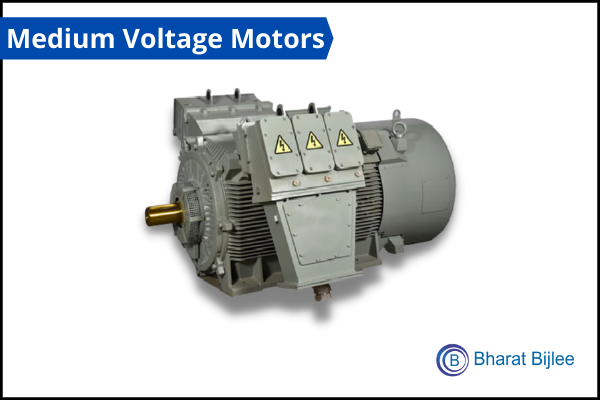

Bharat Bijlee is counted as a forerunner in HV and MV motors manufacturers in India. These motors are manufactured using Bharat Bijlee’s tried and tested DCCA technology, offering high performance and better reliability with the use of dual cooling circuits. These HV and MV motors are suitable for use in various industrial sectors such as Power Generation, Mining, Chemical, Cement, Iron and Steel, Paper and Pulp, Water, Waste Water treatment etc. The motors can serve various applications such as Pump, Compressor, Conveyor, Mill, Fan, Blower, etc.

Bharat Bijlee uses a new efficient cooling system called Dual Circuit Cooling Arrangement (DCCA) for all its High Voltage motors in frame 315 and above. This technology consists of two independent cooling systems which improves the overall cooling of the motor. The primary cooling circuit is the regular stator casing with cooling fins. The shaft mounted external fan blows air over the body fin and cools the motor by forced convection and radiation. The secondary internal cooling circuit consists of rotor with vent holes, an impeller and ventilating passage on the stator body. The air inside the motor is circulated by the impeller which passes through the ventilating passage where it gets cooled on its way from non-driving end to the driving end by the primary circuit. This cool air then passes over the DE overhangs and through the rotor vents to the non-driving end and on its way absorbs heat from the overhangs and from the rotor. This heated air again passes through the impeller to the ventilating ducts and the cycle repeats.

Availability and Reliability are two words that we absolutely abide by at Bharat Bijlee. Our commitment to customer satisfaction makes us one of the most trusted MV motor manufacturers in India.

Medium Voltage Motors

- Voltage – 690 V to 6.6 kV

- Cooling – Type IC 411 / IC 416

- Construction – Horizontal ( IM B3) / Vertical (V1)

- Frame Sizes – MV 315L, MV 355L, MV 400ML & MV 450ML

- kW Range – 160 – 1000 (4 Pole), 160 – 750 (6 Pole), 160 – 560 (8 Pole)

TEFC – BBL TYPE MV

- Frequency – 50 & 60 Hz

- Protection – IP 55/ IP 56

- Starting – DOL / VFD

- Standard – IS/IEC

Standard features:

- Compact TEFC motors for high efficiency in cast iron/ fabricated mild steel construction

- Dual cooling circuit for even temperature distribution

- Bearing cooling fan on DE for lower bearing temperature & longer re-greasing intervals

- Class F Insulation with Class B rise

- Ambient 40 0C & Altitude < 1000M

- Epoxy Mica based vacuum pressure impregnated (VPI) insulation system for long life

- Rotor with Pressure Die cast type Aluminum winding for Ruggedness

- Phase segregated type main terminal box to prevent & withstand high fault levels

- Platinum type RTD s – 6 nos. for windings

- Bearing temperature detectors – 2 No Platinum RTDS. One each at DE and & ODE

- Non-condensation heater

- Suitable for direct drive throw flexible couplings without external thrust

ADDITIONAL OPTIONAL FEATURES (Available on request at extra charge)

- Neutral Terminal Box for Star point

- Dial type Thermometers for bearings with/without contacts

- Suitability for higher Ambient temperature or Altitude

- Suitability for Pulley / gear Drive/ External thrust

- B3/B5 mounting

- Low Vibration and Noise Level

- Copper Bar Construction Rotor

- Insulated Bearing on NDE Side

Bharat Bijlee is the first in India to manufacture and introduce Super Premium Efficiency IE4 motor. Branded as SynchroVERT® our range of IE4 motors combine high efficiency with a host of technologically superior features.

Bharat Bijlee has always been a front-runner in providing energy efficient motors and automation solutions that help our customers reduce the life-cycle energy costs of their motor-driven systems.

To complement our portfolio of IE2 and IE3 motors, we now introduce – for the first time in India – our new range of SynchroVERT® motors that conforms to the Super Premium IE4 class of efficiency motors. With a remarkably short payback period, they offer significant savings over IE2 and IE3 motors along with a host of technologically superior features.

Global warming and its impact on the environment is an ever-growing concern. Governments and companies across the world are actively seeking solutions to a problem that has the potential to profoundly alter the future of our planet. The ever increasing cost of fuel and electricity adds to the complexity, and directly affects not just industries but entire economies. Renewable energy is only part of the solution.

Electric motors are estimated to consume about 65% of the electrical energy consumed by industry. Moreover, energy costs over the typical life cycle of a motor can be as high as twenty times the original capital cost of the motor. Energy efficient motors thus offer an opportunity to significantly reduce energy costs and their collateral environmental effects. Increasingly, there is a strong economic-and environmental-case for choosing high efficiency motors over conventional ones. Instead of repairing or rewinding a failed motor, organizations may profitably consider replacing them with energy efficient motors or motor driven systems that can bring about significant reduction in energy consumption.

Energy Efficient Motors conform to the following standards defined by IEC 60034-30- 1-2014:

- Efficiency Class IE1: Standard efficiency.

- Efficiency Class IE2: High efficiency.

- Efficiency Class IE3: Premium efficiency.

- Efficiency Class IE4: Super Premium efficiency.

Bharat Bijlee’s SynchroVERT® is a range of Super Premium IE4 class Line Start Permanent Magnet Synchronous Motors (LSPMSM)*. These motors do not need a VFD for operation, unlike most PMSMs, and can easily replace existing squirrel cage induction motors. They offer significant savings over IE2 motors.

Advantages of SynchroVERT®

Key benefits of our IE4 LSPMS motor include:

- Online starting.

- Can operate without a VFD.

- Lossless excitation.

- High efficiency.

- High power factor at all loads.

- No rotor losses.

- Runs at synchronous speed.

- Suitable for applications with constant torque below synchronous speed and constant HP above synchronous speed.

- Multiple motors run at exactly the same speed without VFDs: this eliminates speed encoders for feedback control.

- Starting currents are lower than in IE2 motors; starting torque values are similar to IE2 motors.

As these are synchronous motors, the rated speed is synchronous i.e. 1500 RPM. With this motor, a pump or fan will run at about 3% higher speed and it will give much higher discharge/air delivery. Hence if the pump or fan is already fully loading the motor, it cannot be used unless the impellor is redesigned or it is used along with a VFD drive.

In other applications, the higher speed results in more output of the product, eg, spinning frames, textile machines, etc.

Product Range

| Type | Frame | Power (kW) |

|---|---|---|

| IE4 Super Premium Efficiency | 112 to 225 | 1.5 to 45 |